While Liron Topaz was working another sleepless night at TAT Israel’s factory in Kiryat Gat—maintaining and producing cooling systems and heat exchangers for Israeli Air Force jets—a missile from Iran struck the building where his sister lives in Ramat Gan. Her apartment was destroyed, and she and her children were left without a roof over their heads.

“My sister ran to the shelter in her pajamas the moment the siren went off,” Topaz recalls, “Minutes later, there was nothing left of her home. She’s a mother to a reservist son and a teenage daughter. For them, it’s starting from scratch. It feels like becoming homeless overnight. It’s a personal tragedy that reflects the impossible reality we live in here.”

Topaz, the general manager of TAT Israel, offers a perspective that combines the personal and national struggle in Israel since October 7. “F-15 and F-16 jets around the world can’t fly without our parts,” he says. “It’s a tremendous source of pride. Real Zionism. Every time I look up and see jets overhead, I’m filled with pride knowing it all starts in a small factory in Kiryat Gat.”

A war with no breaks

TAT Israel—short for Aviation Accessories Industries—has become one of the hottest stocks on the Tel Aviv Stock Exchange since the war in Gaza began. The company’s share price has risen 90% over the past year and surged 670% over five years, reaching a market cap of about 1.3 billion shekels.

Specializing in cooling systems, thermal management, and engine blades for aircraft, the company supplies both civilian and military clients, including major airlines, the Israeli Air Force, and defense partners in the U.S. and Europe. Its headquarters and main plants are in Kiryat Gat and Gedera.

“Since October 7, we’ve been operating at the highest level of readiness,” says Topaz. “It’s been one long campaign. We hadn’t finished one war when, two weeks ago, we entered a new one. The closure of Israel’s airspace forced us to reorganize and reprioritize our work.”

What does that mean in practice?

“It means finding supply chain solutions and helping the Air Force operate under closed skies. We’ve been working non-stop on refurbishing pumps and engines, specialized defense components, cooling systems, and supporting all air defense systems—like Iron Dome and David’s Sling—that have been operating continuously during Operation Rising Lion.”

How has this affected the workforce?

“In peacetime, about 65% of our sales are civilian, 35% military. But in times like these, Israeli industry cannot pause. It must be war-focused. During heightened military activity, like in the recent conflict with Iran, we worked around the clock to meet demand for parts. I can’t go into details, but our service teams were out in the field more than ever, motivated and committed to maintaining operational readiness of air defense systems.”

When the Iranian attack began, many reservists within the company were called back, despite already serving extended duty in the war in Gaza. “Over the past 18 months, we’ve worked tirelessly. We boosted production capacity, expanded inventory, and prepared backups. On October 8, I was asked if we could re-enable some of our past capabilities. Of course, we did. We brought back former employees, many of them older, to work alongside young staff. Our workforce also includes students through agreements with ORT schools, and women, too, are an increasingly vital part of the company: machinists, grinders. They’re rising fast.”

TAT’s client list includes major civilian and military customers in Israel and abroad. “During times like these, the direct line with our global clients, especially those in the U.S., is crucial,” he adds, referring to the company’s U.S.-based facilities.

“We support maintenance for F-15 and F-16 jets—refurbishing blades, supplying parts for UAVs. Our components are on the planes, on the drones, and in the command systems. The average Israeli doesn’t realize it, but every F-15 and F-16 in the world includes parts made exclusively by TAT Israel. Without our made-in-Israel components from this little factory in Kiryat Gat—those jets don’t fly,” he added.

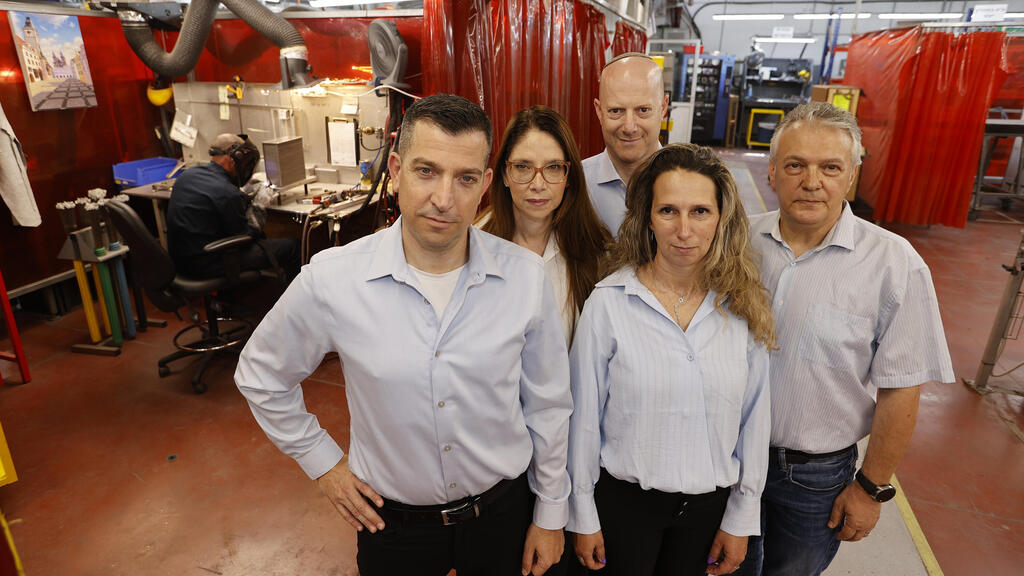

Topaz has emphasized the strong sense of patriotism among its workers since October 7. One of his main tasks, he says, was managing the merger between TAT Israel and Chromalloy’s plant in Kiryat Gat, recently acquired by TAT.

“Yes, profitability matters,” he says, “but so does the emotional well-being of our people. Every morning, I walk the floor, check in with every employee—how they’re doing at home—then we begin the day. A management team that puts people first gets that energy back. Motivation is high. Our team understands how vital Israel’s industrial resilience is. In the end, we’re all in the same place: at war. And we must win.”

Most of the workforce comes from the south: Be’er Sheva, Netivot, Sderot, Kiryat Gat and Gaza border towns. “Some employees have suffered greatly. Some have lost loved ones or have family members who were kidnapped or murdered,” he says.

Ownership change shakes the company

Topaz, 43, lives in Mazkeret Batya with his wife, Einat, and their three children (ages 17, 14, and 11). He holds an MBA from Peres Academic Center and a bachelor’s degree from the Open University. Before joining TAT, he spent 14 years at A.L. Group, a family-owned manufacturer of air, fuel and oil filters for the auto industry. He worked his way up to VP of marketing and business development.

“That’s where I discovered the public sector and became passionate about it," he said. "The Aloni family taught me the importance of empowering employees and creating a family-like atmosphere—values I’ve carried with me as a manager.”

Get the Ynetnews app on your smartphone: Google Play: https://bit.ly/4eJ37pE | Apple App Store: https://bit.ly/3ZL7iNv

TAT Israel is part of TAT Technologies, which trades on both the Tel Aviv Stock Exchange and the Nasdaq. The parent company’s chairman is retired Maj. Gen. Amos Malka, former head of Military Intelligence. CEO Yigal Zamir oversees a company that recently posted over $40 million in quarterly revenue—a 25% increase year-over-year. Net income jumped more than 80% to $4 million, and its order backlog stands at several hundred million dollars.

Despite the impressive growth, the company was recently rocked by a major change: FIMI, the investment fund led by Ishay Davidi, sold its entire 51% stake in TAT. The exit, which yielded massive profits, left the company without a controlling stakeholder. Most of the shares were picked up by Israeli institutional investors, including Meitav, which now holds about 18%.

Was FIMI’s move a surprise? Could it hurt the company?

“I won’t comment on that,” Topaz says. “TAT Israel is strong. We’re a successful Israeli industry, and I’m proud of that.”

What’s next for the company?

“Since TAT Israel was established, we’ve doubled in size. I believe we’ll double again in the next three years, in both revenue and profit. Our growth strategy is to adapt our systems for next-generation aircraft across different global markets.”

Emotional pressure and soccer relief

Topaz remains tight-lipped about specific projects developed since the war began. “Over the past two years, we’ve stayed closely aligned with defense companies and worked with them on new projects,” he says, noting direct ties to the Defense Ministry and the Air Force.

With soaring demand since October 7, is there concern that TAT won’t be able to keep up?

“That thought doesn’t exist. Our workers go out to the field with helmets, return, and go back out again. They know their work matters here in Israel—and abroad. This is national, economic and industrial resilience. There’s no time for fatigue. Every time I hear a jet flying overhead, I get emotional. I know our engine parts are inside that plane. I understand how critical it is to protect Israeli industry, and I remind my workers of that every day.”

And how does he cope with the pressure?

“I have a strong support system—Yigal, Amos, our U.S. colleagues and, most of all, our employees. I also have a coach I work with. It helps to share the emotional load with someone outside the company—especially during times like these, I need to constantly project confidence. I also have a very supportive wife and home. I run at least three times a week, and I play on our company soccer team in the workplace league. We were supposed to play in the Veterans League Final Four, but then the war with Iran broke out. Hopefully, we’ll get back to that soon.”

Is he worried about political events like the banning of the Israeli booth at the Paris Air Show?

“The Paris incident was unnecessary and unfair—but it’s just one event. As global demand grows for munitions and longer flights, cooling systems become essential—that’s our expertise. Spare parts too, all made in Israel. There are defense projects that simply can’t happen without our components. The Israeli government must support its industry, especially the defense sector. Many of the needs now met locally were once sourced from abroad. Israel must aim for industrial independence.”

“TAT Israel is proud to be part of a return to the ‘Made in Israel’ mindset. We’re here to support Israeli industry—and to step up when the country truly needs us.”