Sixteen years after leaving for Boston, Dr. Natan Linder is returning to Israel, this time through his company. Linder founded the 3D printing company Formlabs, one of the leaders in the field, and later the industrial software company Tulip, which is now acquiring the Israeli AI startup Akooda and turning it into its Israeli R&D center.

Akooda’s technology will allow Tulip to integrate AI technologies into its platform. For the Akooda team, this is an opportunity to leave the world of “fantasy” and shift into the real world of engineers, product designers and production lines, helping provide real time insights throughout the manufacturing process.

The value of the deal was not disclosed, but it is unlikely to have reached the valuation the company once received, $20 million, or even the total investment raised so far, $11 million. On the other hand, investors are satisfied, in part because some of the consideration was provided in Tulip equity, and Tulip has been steadily growing for several consecutive years. All Akooda employees will now become Tulip employees, so beyond acquiring the product and customer base, this was very much an acqui hire.

“I began my career at multinational companies in Israel 20 years ago, but my dream was always to come back to Israel in some form, not a simple thing for a global, American company,” Linder tells Ynet. “I tried to recruit Yuval Gonczarowski (Akooda’s CEO) at least twice. It didn’t work out because he had other plans, but when he founded Akooda, we were in close circles and the relationship developed. What I aim to do aligned with what Akooda was building, so at a certain point it made complete sense to join forces. The major potential and opportunity lie in vertical applications, in that space, the connection is natural.”

Tulip is a global company with 300 employees that provides software products for manufacturing engineers as part of the “digital transformation” of industrial production. The company has raised $153 million to date, with its last funding round in 2021 valuing it at $800 million (post money). The company’s headquarters are in Boston, where Linder lives, with additional offices in Munich, Budapest, Singapore, and now Tel Aviv.

Akooda was founded about four years ago by CEO Yuval Gonczarowski and CTO Itamar Nidam, both 8200 alumni who met as students at the Technion. Even before the rise of GenAI, they built a platform that connects to a company’s internal systems, analyzes all ongoing data, and extracts insights that improve management processes.

The Samsung offer and the first connection between hardware and software

Linder’s professional path is worth expanding on. “I was a kid who grew up with a father who was an engineer. I started programming at a very young age,” he says.

In the army, he served in development roles in the Air Force’s intelligence unit, and later worked at Ness Technologies and Sun Microsystems. He studied computer science and business at IDC Herzliya. His entrepreneurial path may have begun there, when he joined the second cohort of the IDC Zell entrepreneurship program. As part of the program, he worked with Eyal Toledano on developing a smart neonatal intensive care mattress. The project never materialized, but Samsung representatives in Israel were impressed and invited the two to establish Samsung Telecom’s R&D center in Israel, developing mobile technologies.

At age 25, he became the head of Samsung’s Israeli branch. “Samsung came to us in 2001 and said they wanted to drive mobile innovation in Israel,” he says. “That was my first real education in how to build large, complex global R&D operations that connect hardware and software.”

In 2008, he left Samsung and returned to entrepreneurship, this time as an entrepreneur in residence at Jerusalem Venture Partners (JVP), working with early stage startups and technologies. Then came the moment that changes careers: “One day my wife came home and said, ‘Pack your bags, we’re leaving.’ She had been accepted to MIT’s MBA program. So we went, with four suitcases and no plan. That’s how we got here, and that’s when my work in advanced manufacturing began, and when the digital and physical worlds came together.”

Linder’s curiosity led him to MIT’s legendary Media Lab, founded in 1985 by Professor Nicholas Negroponte, which trained generations of groundbreaking technologists. Linder was fascinated, applied and was accepted. Every Media Lab student receives a full scholarship sponsored by a major tech company. Linder researched fluid interfaces under Intel sponsorship, and began his PhD in 2011 under Professor Pattie Maes, completing it in 2017. His flagship project was LuminAR, a kind of lightbulb that replaces a computer or phone screen with a projection into the room, adding a digital layer to reality. Augmented reality, without the glasses. The research was funded by Intel, Sony, Qualcomm and Best Buy, but never became a commercial product. The bulb (“bulb” also refers to the bulb of a tulip) remained a symbolic inspiration.

Through Maes, he met Rodney Brooks of Rethink Robotics, creator of the Roomba and the Mars rover robots. “He was the Michael Jordan of robotics for me, and he recruited me to work at his company.”

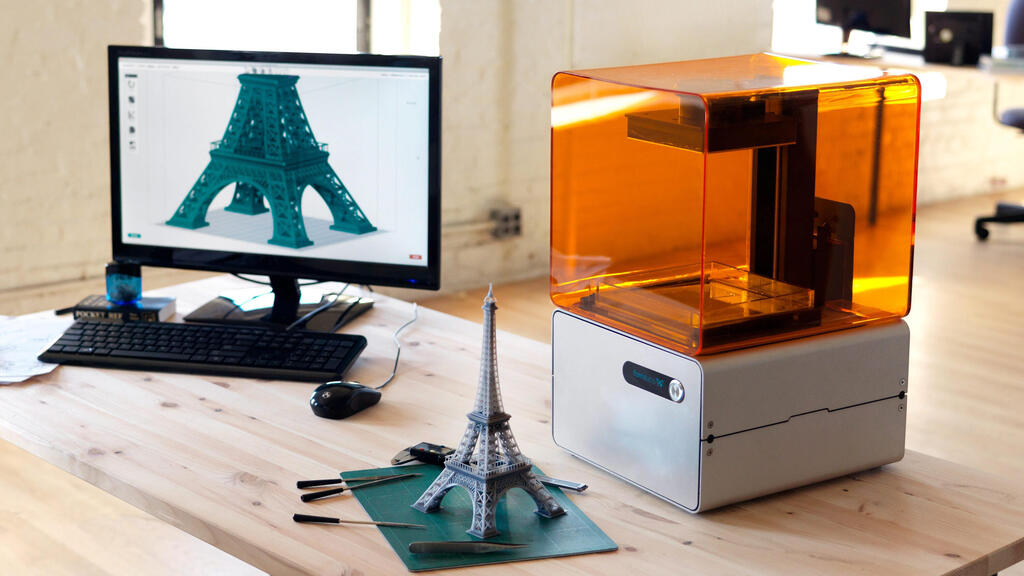

The entrepreneurial bug persisted, and in 2011 Linder paused his studies to found Formlabs with fellow students Max Lobovsky and David Cranor, with Linder as chairman and Lobovsky as CEO. The company rode the rising hype around 3D printing at the time. Formlabs developed personal desktop 3D printers, the kind we once believed we would all have at home. What’s $3,300, the cost of the printer, compared to the joy it could create?

A company with 70,000 customers

The company began with a $3 million Kickstarter campaign, then raised $20 million from VCs, and continued with additional rounds. In 2018 it raised another $15 million. Linder said at the time: “We’re a real unicorn, not inflated. We’re not building a $1B company, but a $10B company.” In those years, Formlabs grew rapidly and became a rising star, with media attention calling Linder the “Steve Jobs of 3D printing.”

Many 3D printing companies have since shut down, but Formlabs is still active. The printers have become more industrial, part of what is now known as additive manufacturing, producing plastic or metal parts layer by layer instead of using molds. Customers include product designers creating prototypes, as well as medical applications such as printed bones, orthopedic supports, and dental solutions.

Formlabs has raised $250 million since its founding and today operates profitably, with 70,000 customers. “Nearly every company in the world that produces something physical uses Formlabs’ technology to reduce R&D costs,” Linder says.

Back in 2009, at Brooks’ company, Linder found himself on factory floors, recognizing the enormous gap between the outdated management technologies used in factories and the cutting edge of the IT world. “Operational and control engineers, the machines, planning, safety. They all do data and logic driven work, but they don’t have Monday.com and they don’t have Salesforce, they work with paper and Excel,” he says.

That insight led to the founding of Tulip in 2014. “The core of Tulip was people who worked together at MIT. With our deep exposure to manufacturing, there came a moment where we said: ‘Either we build this or someone else will.’ It was one of those moments when you tell yourself you don’t want to look back and say: ‘That was a great idea, but we didn’t build it.’”

Tulip’s idea was a platform designed for how manufacturing engineers actually work, communication with machines, process definition, monitoring engine performance, imaging production lines. This was before the AI boom, yet Tulip built technology that lets engineers create manufacturing apps without writing a single line of code.

Did you foresee the no-code boom back in 2014?

“I don’t think we predicted the future, we simply saw a real customer problem. There aren’t enough software engineers in the world, especially in manufacturing. These environments are complex, constantly changing with supply chain evolution, engineering changes, and ongoing worker training. No-code is very natural for this world. You take people out of Excel and put them in this environment, suddenly they’re building manufacturing flows.”

How did AI change your product?

“Tulip partners with giants like Microsoft and Amazon. But 7–8 years ago, you couldn’t even say ‘AI’ or ‘machine learning’ inside the company, anyone who understood the space knew that without enough data and interfaces, it was just propaganda. We started working with Microsoft two years ago and released the first copilot to the market. The thesis was clear: this is going to impact everything, and as a platform we need to think about it holistically. For example, enabling you to throw a PDF or a video into Tulip, and it generates the manufacturing flow.”

In 2021 Tulip raised $100 million and hasn’t raised since. What happened?

“The company grew across every metric, roughly 5–6x, and continues to grow. We were affected by trade wars, tariffs and, unfortunately, real wars. Manufacturing took several hits. The first, of course, was COVID, which made the need for technology extremely clear.”

Are you profitable today?

“We’re not profitable yet, but we’re at the stage where we can see it. Most companies were addicted to VC funding cycles every 18 months. Tulip never played that game. we’ve raised only $153 million in the company’s lifetime. We’re now balancing growth and profitability. We are getting closer to triple digit ARR with 40% growth, and our last valuation was $800 million. People asked if I built a herd of unicorns, but that doesn’t matter. Many of those unicorns turned into zombie corns.”

Are you planning another funding round — or perhaps an IPO?

“If an opportunity arises that fits the company’s needs, we’ll consider it. But we won’t raise just for the sake of raising. There are many players in the ecosystem, like Nvidia, Microsoft, so it’s possible that funding could come from that direction.”

Could a giant like those companies acquire you?

“It’s possible, but that’s not the goal. There is space in the market for an independent company focused on this operational layer of engineers and their management stack. Just as sales and marketing have Salesforce, and HR has Workday. Tulip can become the Salesforce of operations. It will require hard work, and it could take 15 years, but that’s fine, we’re young.”

The Akooda team brings Tulip deep expertise in artificial intelligence, large language models, and advanced enterprise search technologies, capabilities that directly strengthen Tulip’s mission to empower frontline manufacturing workers with intelligent tools. All eight Akooda employees will move to Tulip’s R&D center in Tel Aviv and work closely with the company’s engineering team in Munich. Previously, Akooda raised $11 million from investors including NFX, Village Global (an investment fund backed by leading entrepreneurs such as Jeff Bezos, Bill Gates and Mark Zuckerberg), Founder Collective, one of Uber’s first investors, and the investment arm of software giant Atlassian.

“Akooda was built to make organizations smarter by connecting people and data through AI,” says Yuval Gonczarowski, Akooda’s CEO and now a product lead at Tulip. “Joining Tulip allows us to bring this vision into the heart of manufacturing processes, where real-time intelligence can have enormous impact. Akooda has a significant number of developers with deep cybersecurity experience (alumni of Adallom/Microsoft), people who came to show that we can excel in other domains as well, exciting domains with meaningful impact.”